| JK Moving Services / Sterling, VA |

| 2003 | 2004 | 2006 | President Bush’s Visit | 2008 | 2011 |

MAR 13 – 17, 2011 STERLING, VA — Nearly 150 employees sent a power surge through JK Moving Services by becoming IOMI® Certified Office Movers®.

The energy of all sales and operations employees including move helpers spiked during IOMI® best-practice methods training held at JK’s Commercial Division facility, the tenth such training session by the International Office Moving Institute (IOMI®) at the company’s Sterling, VA headquarters.

Students cycled through training activity stations every 45 minutes, receiving instructions from JK’s project and commercial account managers as well as IOMI® Instructor Ed Katz.

JK’s IOMI® Certified Office Mover® training included the Boxless Move®, minimizing the risk of damage to office buildings, and protecting servers, monitors, printers and CPUs with two layers of anti-static bubbles. Most competitors wrap computer components with cheaper (but also very risky) quilted pads.

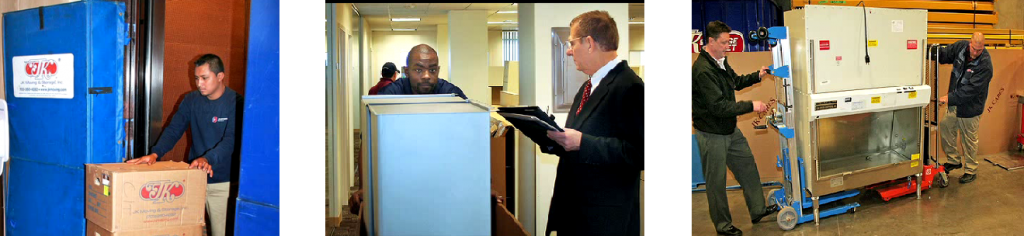

Students were also trained and IOMI®-certified to move labs.

(L-R) Rocco Balsamo, Director of Sales; Kris Smurda, Commercial Operations Manager; and Ted Isaacson, Vice President/General Manager Commercial Services

(Top) Aaron Shaffer, Senior Project Manager, teaches a truck loading class.

(Right) Laura Ware, Commercial Account Manager, helps train movers.

Space GobblersTM in desk drawers is part of JK’s Boxless Move® service.

Crew practices the best method for moving a fragile conference room table.

The most efficient method to move library books.

How to safely move fragile glass.

Dave Ross, Commercial Warehouse Manager, inspects JK’s inventory of four-wheel dollies.

JK protects every piece of electronic equipment with two layers of anti-static bubblewrap.

JK uses specialized lifting equipment to hoist and move fragile, bulky, or heavy lab equipment.

(L-R) Kris Smurda, Commercial Operations Manger, Jim Stevens, Commercial Account Manager, Rocco Balsamo, Director of Sales

The Audit

On Thursday, March 17, Instructor Ed Katz randomly selected a JK job in progress to measure how well the crew followed IOMI’s® best practice methods just learned during training.

For adhering to IOMI® high standards during a move of several truckloads for ICF International, the crew scored near the top of the range.

Very early on the morning of the audit, JK’s fleet of more than 200 units all had wheel chocks in place to prevent them from rolling should the emergency brakes fail. On the job site during the audit, Katz found all trucks secured with wheel chocks.

At the job site, Instructor Ed Katz met Patricio Aguilar, Project Manager, who was running the job.

JK’s Mat-A-Doors® protect elevator entrances, an IOMI® best practice method for minimizing the risk of damage to office buildings.

Recycling

JK Moving Services is serious about recycling. In 2010, JK diverted 2,131,910 pounds or 1,066 tons of recyclable materials away from area landfills. JK’s recycling program includes metal, electronics, cardboard and office furniture.

Electronics are sorted.

Cardboard is compacted and bundled.

JK’s crusher pulverizes furniture into a fine powder that’s picked up by a recycler.

(L-R) Ed Katz, IOMI® Instructor, Brian McGuinness, Corporate Sales Manager, Business Development; Rocco Balsamo, Director of Commercial Sales; Stephen Dezelak, Commercial Account Manager; and Kelly Whitfield, Manager, Business Development